Thermal-bonded soccer balls weren’t always the standard. For many years, stitched balls were used at every level of the game, including the biggest tournaments in the world. That didn’t change all at once. As the sport evolved, so did expectations around how the ball should perform. If you watch top-level matches today—World Cup games, professional leagues, and even a growing number of college and high-school competitions—you’ll notice that thermally bonded balls are now everywhere. It’s not because stitched balls suddenly stopped working. The game simply started demanding more. Faster play, harder surfaces, and unpredictable weather exposed the limits of traditional construction, pushing organizers toward balls that hold their shape and feel the same deep into the match.

In this article, we’ll take a closer look at how thermal-bonded soccer balls developed, how their construction has evolved over time, and what structural advantages they offer on the field. We’ll also explain why elite competitions and leading manufacturers have largely moved on from stitched balls in favor of modern bonded designs.

A. History and Evolution of Thermal-Bonded Soccer Balls:

To understand why thermal-bonded soccer balls appeared, you first have to look at what stitched balls could—and could not—do. Before thermal-bonded soccer balls existed, stitched construction was simply how elite match balls were made. Up through the early 2000s, there wasn’t an alternative. Balls used in FIFA competitions and major professional leagues were all stitched, whether by hand or by machine. At the top end, these balls were well made and generally reliable. Even so, the basic design came with limits that never fully went away, no matter how much manufacturing quality improved.

Water absorption was the most persistent issue. Stitching requires needles to pass through the outer cover, and that process creates tiny openings along every seam. Those openings cannot be fully sealed. In dry conditions, the effect is minimal. In wet conditions, the effect shows up fast. Water works its way into the ball, the weight starts to climb, and balance changes. The ball no longer moves the same way through the air. This isn’t something that only appears late in a match. Depending on how much rain there is and what the pitch is like, the change can happen early on.

This showed up most in European football. In places like the United Kingdom, the Netherlands, Belgium, and Germany, the game is played all year, and wet conditions are common. Rain and damp pitches are normal there. As a match wears on in those conditions, a stitched ball starts taking on water. It gets heavier, control suffers, and the way the ball moves through the air becomes less stable.

Stitching also creates a structural limitation. Seams are stress points. Every strike, clearance, and long pass places load on the threads holding the panels together. Over time, those threads fatigue. They loosen, stretch, or break, even when the outer synthetic material is still usable. Once that happens, panel alignment suffers, roundness is lost, and performance drops off.

By the late 1990s, it was becoming clear that stitched construction had reached its practical limit. The method was originally developed for leather balls and a slower style of play. With modern synthetic materials and higher performance demands, the same approach no longer made sense at the top level. That realization is what pushed manufacturers to look for a different way to build match balls.

i. Inspiration Behind Thermal Bonding:

There isn’t a single, clearly documented inventor of the thermal-bonded soccer ball. What industry research does show is that early versions started to appear in the early 2000s. These were not products sold to the public. They were experimental prototypes developed internally by major brands as part of long-term research and testing programs.

Thermal or heat-activated bonding itself wasn’t new when it started showing up in soccer balls. That idea had already been around. By the late 1990s, other industries were using similar bonding methods. Examples include Athletic footwear where heat-fused overlays were used instead of stitched reinforcements, and performance apparel was doing the same with seam-sealed construction. In both cases, stitching was being phased out where bonding made more sense. Heat bonding was also common in inflatable products, molded synthetic goods, and even automotive interior manufacturing. The underlying technology was proven long before it reached soccer balls.

Because of this existing foundation, applying bonding methods to soccer balls became technically realistic once synthetic PU materials started replacing natural leather. The materials were more consistent, more controllable, and better suited to heat-based processes than traditional leather covers.

Soccer experts have credited Adidas for introducing thermal bonded soccer balls. The company’s R&D team helped transition these concepts from internal prototypes into match balls that could be manufactured at scale and used in official competition.

ii. First Official Use at the Elite Level:

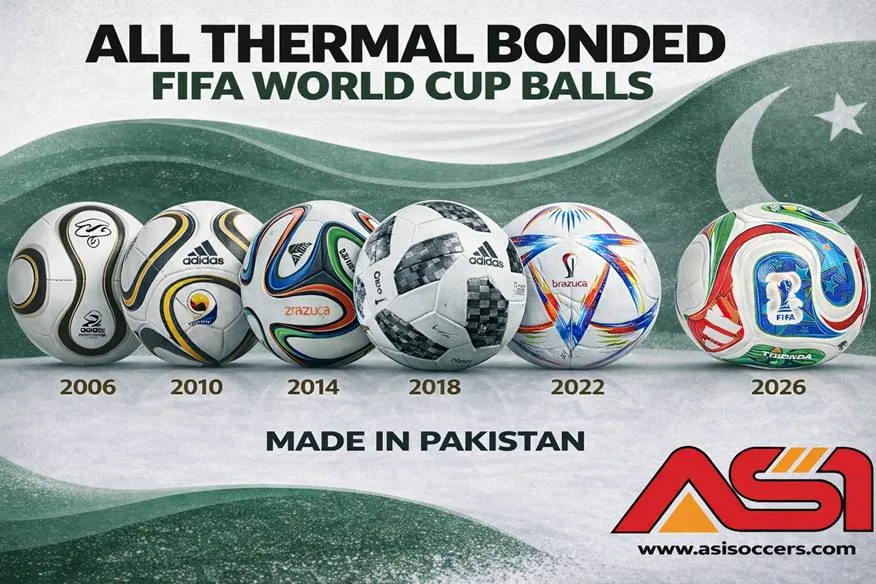

The first fully thermally bonded soccer ball used in top-level competition was the Adidas Teamgeist, introduced as the official match ball for the 2006 FIFA World Cup.

This period ended up being a real turning point in soccer ball design. Compared to stitched balls, these new models stood out for having almost no water absorption, better roundness, and much more stable flight during play.

Between 2008 and 2014, thermal-bonded balls began showing up everywhere at the top level including in UEFA competitions, European domestic leagues, and international tournaments. During those years, manufacturers kept adjusting panel layouts as well as experimenting with designs such as 8-panel and 14-panel formats, along with updated versions of the traditional 32-panel structure.

Thermal-bonded construction is what we see in most elite matches today. Stitched balls haven’t disappeared, but they’re now used mainly for training, recreational play, or lower-priced products. Hybrid balls sit somewhere in between, combining elements of both constructions.

FACT: ALL THERMAL BONDED FIFA WORLD CUP SOCCER BALLS ARE MADE IN PAKISTAN

B. What Is a Thermally Bonded Soccer Ball?

A thermally bonded soccer ball differs construction wise from stitched soccer ball. Instead of sewing panels together with thread, the panels in thermal bonded balls are fused together using controlled heat, pressure, and specialized adhesives, creating a seamless outer shell.

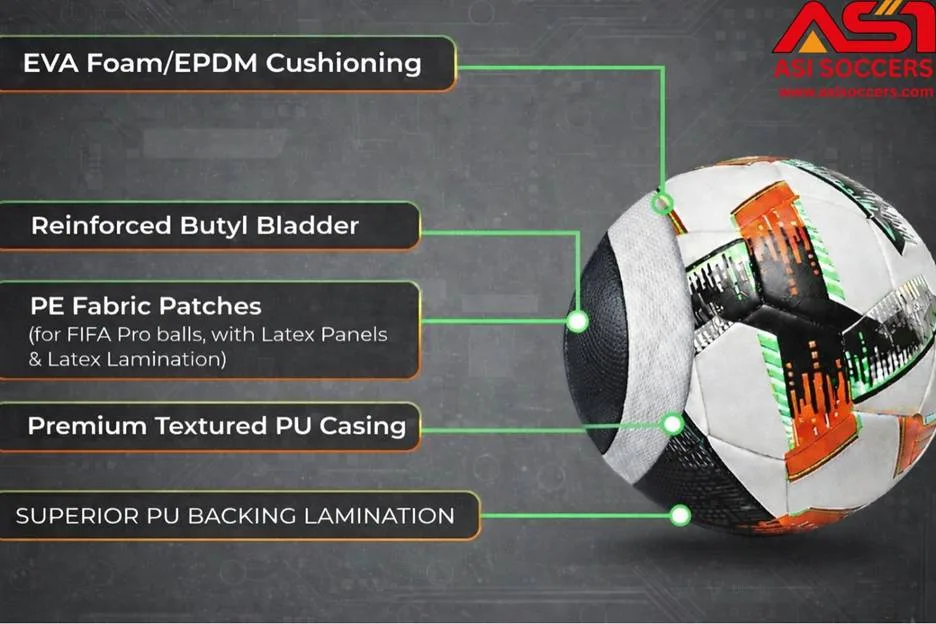

A thermal-bonded soccer ball consists of following three primary components typically:

1. outer synthetic cover

2. internal bladder

3. foam backing layer

Each component plays a critical role in performance and durability.

i. Outer Cover Material

The outer cover of a thermal-bonded soccer ball is typically made from PU (polyurethane) synthetic leather. The quality of this PU leather vary significantly from manufacturer to manufacturer with premium balls demand use of high-grade PU due to its durability, low moisture absorption, and consistent surface properties.

Textured soccer balls are often featured in Elite matches to enhance grip, control, and aerodynamic stability. Common textures include diamond patterns, micro-dot or golf textures, and microfiber finishes used by leading global brands.

PU covers may be produced with:

• no backing

• standard fabric backing

• multi-layer foam or fabric reinforcement

Backing layers directly influence touch, softness, and perceived quality.

At ASI Soccers (Arbish Sports Industries), we source and work with a wide range of PU materials and backing constructions, allowing ball specifications to be tailored precisely to the intended level of play.

Thermal bonding needs PU materials capable of withstanding higher temperatures without degradation. Since Inferior materials may deform under heat, manufacturers then rely on manual gluing rather than true thermal bonding—resulting in inconsistent quality. ASI Soccers uses high-temperature-resistant PU materials and industrial-grade bonding adhesives designed specifically for thermal construction.

ii. Bladder Construction

The bladder is responsible for air retention, rebound, and internal pressure stability.

Common bladder types include:

• latex

• butyl

• SR/Synthetic Rubber

While latex bladders provide excellent rebound and a lively feel, their air retention is lower due to their porous structure. For this reason, they are typically used in elite match balls, where frequent inflation is acceptable.

Butyl bladders offer superior air retention but produce a firmer feel. Pure butyl is rarely used alone in match balls, as it can feel overly rigid. Instead, hybrid constructions are common, such as:

• B30 (30% butyl)

• B50 (50% butyl)

• B80 (80% butyl)

Bladder with higher butyl content will have better air retention but lower rebound and vice versa.

Patched Bladders (Carcass Construction):

Modern soccer balls increasingly use patched bladders, sometimes referred to as carcass construction.

An unwound bladder expands unevenly when inflated, placing irregular stress on the outer panels and bonded seams. This can compromise roundness, bonding strength, and flight stability.

Patching restrains bladder expansion, ensuring:

- uniform internal pressure

- improved shape retention

- stable and predictable ball flight

This construction has become standard in high-quality modern soccer balls.

iii. Foam Backing Layer

Between the outer cover and bladder lies the foam backing layer, a critical component in thermal-bonded balls.

The foam:

• distributes impact forces evenly across panels

• supports bonded seams from the inside

• controls touch, rebound, and feel

The most commonly used foam is EVA (Ethylene-Vinyl Acetate) due to its lightweight nature, thermal stability, resilience, and ability to recover shape after repeated impacts. EVA foam enables thermal-bonded balls to maintain consistent performance throughout their lifespan

Having covered the evolution and construction of thermally bonded soccer balls, we can now examine why professional leagues are moving away from stitched balls. As discussed, stitching inherently creates needle holes, through which water can enter ball, weaken seams, and introduce manufacturing variability. Over time, stitched balls degrades, lose roundness, and deteriorate faster under aggressive environments.

Thermal-bonded balls eliminate these weaknesses by:

• removing needle holes entirely

• reducing water absorption to near zero

• improving shape consistency through precision molding

• increasing seam durability

• delivering more predictable flight and touch

For professional leagues, where consistency, fairness, and performance in all conditions are essential, thermal bonding represents a clear technological advancement over traditional stitching.

ASI Soccers is one of the leading manufacturers of premium thermal bonded soccer balls based in Sialkot, Pakistan. We have produced FIFA quality pro soccer balls for established and emerging brands. If you are looking to manufacture Elite thermal bonded soccer balls, contact ASI soccers today.

- Why Thermal Bonding Is Replacing Stitching in Professional Soccer Leagues: The 1 Proven Guide by ASI Soccers

- NFHS Authenticating Mark Program: The #1 Essential Guide Sports Brands Can’t Ignore

- Sialkot shines globally as the official FIFA World Cup 2026 balls are made in Pakistan

- What Type of Soccer Ball Matches Your Playing Style?

- How Pakistan Leads Soccer Ball Production