How Pakistan Produces Most of the World's Soccer Balls

Table of Contents

ToggleSoccer, known as the “beautiful game,” is loved by billions worldwide. It is a unifying sport, from World Cup finals to casual games in the park. Yet, a lesser-known story lies at the heart of this global phenomenon: most of the world’s soccer balls manufacture made in a single city in Pakistan—Sialkot. This blog explores the fascinating history, craftsmanship, challenges, and global impact of Pakistan’s role in producing soccer balls.

1. The Soccer Ball Hub: Sialkot, Pakistan

Sialkot, a small industrial city in Punjab, Pakistan, is known as the global capital of soccer ball manufacturing. Nearly 70% of the world’s hand-stitched soccer balls originate from this city, which supplies major brands like Adidas, Nike, and Puma.

Why Sialkot?

Sialkot’s prominence in soccer ball production stems from:

A Historical Legacy

The city began manufacturing soccer balls in the late 19th century during British colonial rule. British soldiers stationed in the region brought the game and its equipment, which inspired local artisans to create soccer balls.

Skilled Workforce

Generations of craftsmen have passed down stitching and manufacturing techniques, fostering a unique skill set in the local population.

Adaptability

Sialkot manufacturers have consistently evolved to meet changing industry standards and technological advancements.

2. The Manufacturing Process

Creating a soccer ball in Sialkot is an intricate process that combines traditional hand-stitching techniques with modern technology.

A Step-by-Step Guide to Making a Soccer Ball:

Material Selection

High-quality synthetic leather or polyurethane sheets are used for the outer layer. These materials ensure durability, water resistance, and consistent performance.

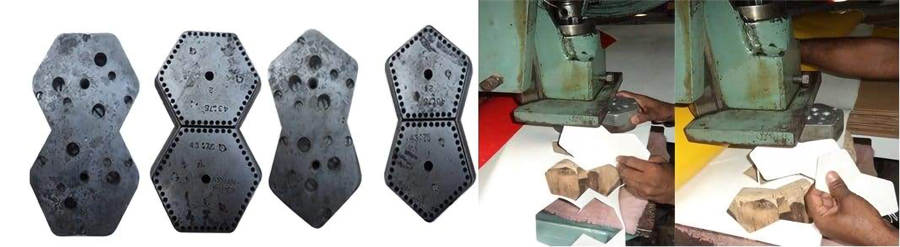

Panel Cutting

The leather is cut into hexagonal or pentagonal panels using precision machinery. Modern manufacturing requires standardized shapes to ensure aerodynamic consistency.

Printing and Branding

Panels are printed with logos, brand names, and designs. Leading brands like Adidas often require meticulous attention to detail to meet their branding requirements.

Stitching

The hallmark of Sialkot soccer balls is hand-stitching. Skilled workers use durable polyester thread to stitch panels together. Each ball can take 2-4 hours to complete, depending on the complexity.

Inner Bladder Insertion

An inflatable rubber bladder is inserted into the stitched panels to provide shape and bounce.

Quality Control

Each soccer ball undergoes rigorous testing for durability, performance, and air retention.

The Role of Technology

While hand-stitching remains a defining feature of Sialkot soccer balls, automation is increasingly used for tasks like panel cutting and printing. This combination of tradition and technology allows Sialkot to maintain quality while scaling production.

3. Impact on the Global Market

Sialkot’s soccer ball industry plays a vital role in global soccer culture, supplying balls for:

Grassroots Soccer Programs

Affordable yet durable balls made in Sialkot help promote soccer in developing countries.

Major Tournaments

Sialkot-made balls have been used in prestigious tournaments, including the FIFA World Cup.

A Game-Changer: FIFA World Cup 2014

In 2014, Sialkot-based Forward Sports manufactured the Adidas Brazuca, the official match ball for the FIFA World Cup in Brazil. This achievement placed Sialkot firmly on the global stage, showcasing the city’s manufacturing excellence.

4. The People Behind the Craft

The success of Sialkot’s soccer ball industry is deeply rooted in its workforce. Approximately 60,000 workers are employed in the city’s sports manufacturing sector.

Hand-Stitchers: Unsung Heroes

Most hand-stitchers are women, who work in small workshops or from home. Their skill and attention to detail ensure that each ball meets international standards.

Stitchers earn an average of $100–$150 per month, a modest but vital income for many families.

Challenges Faced by Workers:

Low Wages

Despite their craftsmanship, many workers earn wages that barely cover living expenses.

Health Concerns

Hand-stitching for hours can lead to musculoskeletal issues and other health problems.

Child Labor Concerns

Although significant progress has been made to eliminate child labor from the industry, it remains a challenge for some informal workshops.

5. Challenges for the Industry

Despite its global dominance, Sialkot’s soccer ball industry faces numerous challenges:

a. Competition from China

China has emerged as a major competitor by producing machine-stitched soccer balls at lower costs. While these balls lack the craftsmanship of Sialkot’s hand-stitched versions, they dominate markets seeking cheaper alternatives.

b. Economic Pressures

Fluctuating exchange rates, inflation, and rising raw material costs affect Sialkot manufacturers’ profit margins.

c. Sustainability Demands

As environmental concerns grow, there is increasing pressure to adopt sustainable practices, such as using eco-friendly materials and reducing waste.

6. Innovation and the Future

To stay competitive, Sialkot’s manufacturers are embracing innovation:

Technological Advancements

Thermal Bonding

Forward Sports pioneered thermal bonding technology, which eliminates the need for stitching and improves ball consistency.

Smart Soccer Balls

Some companies are experimenting with sensor-embedded balls to track data like speed, spin, and trajectory.

Certifications and Ethical Practices

Fair Trade Certification

Manufacturers are increasingly obtaining certifications to assure buyers that workers are paid fairly and labor standards are upheld.

Sustainability

Eco-friendly initiatives, such as biodegradable materials, are gaining traction.

7. Economic and Social Impact on Pakistan

Contribution to Pakistan’s Economy

- Sialkot’s sports manufacturing sector generates billions of dollars in annual exports.

- The soccer ball industry supports auxiliary businesses, such as transportation, packaging, and raw material suppliers.

Social Development

- The industry has uplifted thousands of families, providing steady income and skill development opportunities.

- Initiatives by international brands and NGOs, such as building schools and clinics, have improved community welfare in Sialkot.

8. Cultural Significance of Soccer Balls

Beyond economics, the soccer ball holds cultural significance:

For Pakistan, it is a symbol of craftsmanship and resilience.

For soccer players and fans worldwide, it represents the joy of the game.

9. Global Recognition and the Road Ahead

Sialkot continues to enjoy global recognition for its soccer ball production. However, staying at the forefront requires addressing challenges and leveraging opportunities.

Key Strategies for the Future

Investing in Worker Welfare

Improving wages and working conditions will ensure a motivated and skilled workforce.

Strengthening Branding

Highlighting Sialkot’s craftsmanship and ethical practices can help the industry differentiate itself.

Expanding Product Lines

Diversifying into related sports equipment can boost revenue streams.

The story of how most of the world’s soccer balls are made in Pakistan is a testament to the power of craftsmanship, resilience, and global collaboration. Sialkot has carved a niche in the world of sports, supplying the very heart of the beautiful game—the soccer ball.

As the industry evolves to meet modern demands, Sialkot’s manufacturers, workers, and visionaries will undoubtedly continue to shape the future of soccer. From the backyards of small towns to the grand stadiums of international tournaments, Sialkot-made soccer balls will remain at the center of the action.

This legacy is a source of pride for Pakistan and an inspiration for artisans worldwide, proving that small communities can achieve global impact through skill, innovation, and perseverance.

- Facebook

- Twitter

- Linkedin

- Whatsapp