The Intricate Process of Large-Scale Hand-Sewn Soccer Ball Manufacturing

Table of Contents

ToggleSoccer, known as the world’s most popular sport, owes a significant part of its charm to the soccer ball itself. From neighborhood matches to international tournaments, the soccer ball is at the heart of the game. Have you ever wondered how these iconic spherical companions come to life? In this blog post, we will take a detailed journey through the fascinating process of large-scale soccer ball manufacturing, uncovering the materials, machinery, and techniques involved in crafting these symbols of the beautiful game.

Materials: Crafting the Foundation

Sheets of Leather or Synthetic Material

The Backbone of the Ball: The choice of material impacts the ball’s quality and durability. When it comes to crafting soccer balls, the fundamental material choice holds significant sway over the ball’s performance, longevity, and overall feel. The manufacturing process begins with the selection of either genuine leather or synthetic materials, each carrying its own set of characteristics and considerations.

1. Leather: A Classic Choice

Tradition and Elegance: Leather soccer balls evoke a sense of nostalgia and authenticity, harkening back to the early days of the sport.

Premium Feel: Genuine leather provides a soft touch and comfortable grip, making it favored by some players.

Craftsmanship: Leather balls require meticulous craftsmanship to ensure consistent quality, making them a choice for high-end markets.

Natural Variation: Leather’s organic nature results in slight variations in appearance and texture, adding to the ball’s uniqueness.

2. Synthetic: Modern Efficiency

Cost-Effectiveness: In the realm of large-scale manufacturing, synthetic materials shine due to their lower production costs, making soccer balls more accessible to a broader audience.

Consistency: Synthetic materials offer uniformity in texture, shape, and performance, minimizing variations between individual balls.

Durability: Synthetic materials are engineered to withstand rigorous play and diverse weather conditions, extending the ball’s lifespan.

Versatility: Manufacturers can experiment with different synthetic compounds to tailor the ball’s characteristics to various playing styles and environments.

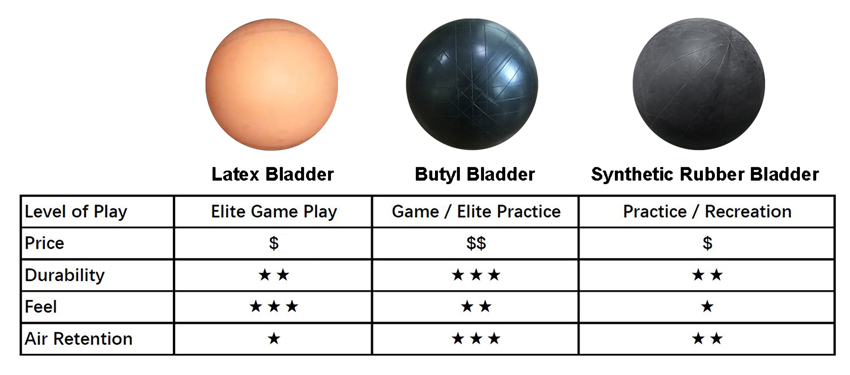

3. Bladders: Bouncing Inside

Beneath the Surface: Bladders provide the ball’s bounce and shape. While the exterior panels of the soccer ball capture our attention, it’s the inner bladder that gives the ball its bounce and structural integrity. Bladders are essential components that contribute to the ball’s responsiveness and playability.

Rubber or Synthetic Construction: Bladders are typically made from either natural rubber or synthetic materials like latex or butyl. These materials offer the necessary elasticity to maintain the ball’s shape while allowing it to rebound effectively.

Air Retention: Bladders are designed to hold air pressure, which directly influences the ball’s bounce and responsiveness during play.

Precision Engineering: Advanced manufacturing processes ensure that bladders are consistent in size, shape, and material composition, contributing to a standardized playing experience.

Automated Insertion: In the large-scale production setting, automated machines are employed to insert bladders into the ball’s panels, ensuring uniform placement and inflation.

4. Thread and Needles

Stitching Strength: Thread and needles are essential for joining the panels.

Double Stitching: The double-stitching technique enhances the ball’s robustness.

Manufacturing Process: Piecing it Together

1. Pasting/Laminating Fabric Layers on Panels

Enhancing Durability: Strengthening the ball’s core through layered construction. In the pursuit of durability and resilience, soccer ball panels undergo a crucial step, the application of fabric layers. This process involves adding extra layers of fabric to reinforce the panels, ensuring they can withstand the intense play and varying weather conditions.

Layered Construction: Fabric layers are pasted onto the panels, creating a robust core that enhances the ball’s structural integrity.

Reinforcement: These added layers contribute to the ball’s ability to maintain its shape, withstand impact, and resist wear and tear.

Consistency and Precision: Automated equipment ensures precise application of fabric layers, maintaining uniformity across all panels.

Impact on Performance: The strengthened panels contribute to the ball’s longevity, making it a reliable companion on the field for countless matches.

With fabric layers securely applied, the soccer ball’s construction is fortified, ready to face the challenges of the game while offering consistent performance over time.

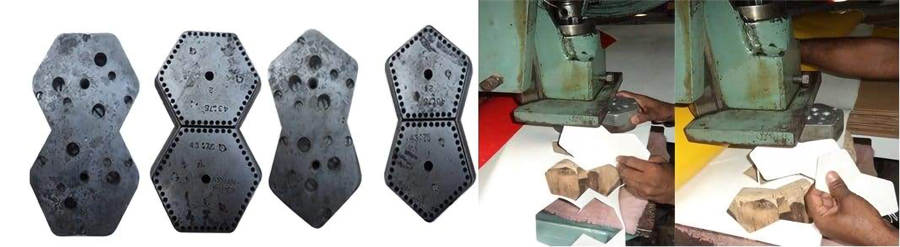

2. Cutting the Panels

Precision Cuts: Cutting machines shape leather or synthetic sheets into hexagonal and pentagonal panels.

Panel Variety: Panel number and arrangement vary based on ball size and type.

3. Printing on Panels:

Adding Identity and Design: The art of branding and aesthetics. The process of printing on panels is a pivotal step that imbues soccer balls with their distinct visual identity. It’s at this stage that the ball’s branding, logos, and designs come to life, reflecting the manufacturer’s artistry and the essence of the sport.

Manual Precision or Automated Efficiency: Depending on the scale and intricacy of the design, printing can be done manually or using automated machines for efficiency.

Branding and Logos: Manufacturer logos, sponsorships, and other branding elements are carefully printed onto the panels, providing recognition and authenticity.

Custom Designs: Special edition balls and tournament models often feature unique designs that celebrate specific events or themes, making each ball a collector’s item.

Aesthetic Appeal: The printing process contributes to the ball’s aesthetic appeal, adding a touch of personalization and visual allure to the final product.

As soccer balls roll off the printing line, they don’t just carry a brand; they carry the spirit of the game itself. With branding firmly in place, the balls are ready to embark on their journey to players, fields, and arenas worldwide.

4. Punching Holes

Pre-Stitching Prep: Punching machines create holes for stitching.

Customized Placement: Hole count and layout are tailored to each ball design.

5. Skillful Stitching

The Art of Sewing: Skilled workers sew panels together with precision.

Automated Stitching: Stitching machines enhance speed and consistency.

6. Bladder Insertion

Automated Precision: Bladders are inserted using automated machines.

Ensuring Uniformity: Automated processes guarantee even bladder placement.

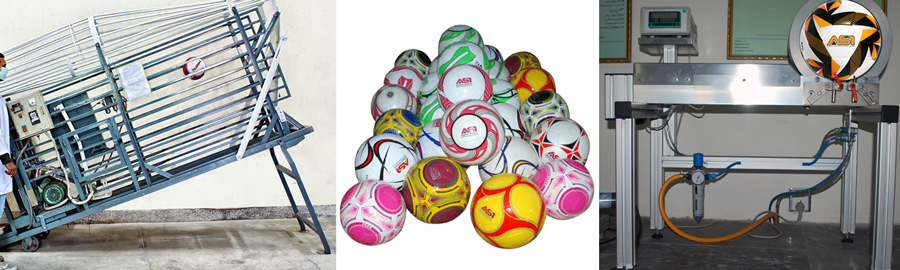

7. Inflation Process

Perfect Pressure: Inflators adjust the ball to the desired pressure.

Performance Impact: Correct inflation affects bounce and playability.

8. Quality Testing

Roundness and Bounce: Automated equipment tests balls for roundness and proper bounce.

Meeting Standards: Testing ensures balls conform to quality and performance benchmarks.

9. Finishing Touches

Cleaning and Washing: Cleaning and washing are the final steps in the soccer ball making process, ensuring each ball meets the highest quality standards.

Manual or Automated: Cleaning and washing methods vary, blending craftsmanship and efficiency to remove any impurities and leave the soccer balls looking pristine.

10. Packaging the Precious

Protection for Transit: Packing materials safeguard balls during shipping.

Boxes and Bags: Cardboard boxes and bags are commonly used packaging options.

11. Global Shipping

The Final Journey: Balls are shipped worldwide to retailers and distributors.

Logistics Variety: Trucks, ships, and airplanes ensure global distribution.

Conclusion: Where Craft Meets Technology

The journey from raw materials to the gleaming soccer balls adorning stadiums worldwide is a testament to the synergy between traditional craftsmanship and cutting-edge technology. Large-scale soccer ball manufacturing showcases the intricacies involved in creating an object that bridges cultures, continents, and generations. As you watch the next thrilling match, remember the remarkable process that brought that ball to life, uniting players and fans around the globe.

- Facebook

- Twitter

- Linkedin

- Whatsapp