The Evolution of Soccer Ball Materials: From Leather to High-Tech Marvels

Table of Contents

ToggleComparing Soccer Ball Materials: Leather, PU, TPU, and PVC

The soccer ball has come a long way, evolving alongside advancements in materials and technology. From traditional leather to modern synthetics like PU, TPU, and PVC, the materials used in soccer ball construction profoundly impact their flight, touch, durability, and overall performance. This article delves into the materials that shape the game and explores their effects on the playing experience.

Introduction to Soccer Ball Materials

Soccer balls have undergone significant transformations over the years. Today’s balls are meticulously engineered using advanced materials that optimize performance, durability, and player satisfaction. Understanding the materials used in their construction can help players, coaches, and enthusiasts select the perfect ball for their needs.

The Outer Layer: The Ball’s Skin

The outer layer, or skin, of a soccer ball, is its first line of interaction with players and the environment. This layer significantly influences the ball’s feel, durability, and aerodynamics. Here are the most common materials used:

1. Leather

Leather was once the standard for soccer balls, prized for its exceptional touch and natural feel. However, its limitations, particularly in wet conditions, have seen it largely replaced by synthetic materials.

Advantages:

- Exceptional touch: Leather offers a premium, unmatched feel.

- Traditional appeal: Many players enjoy the nostalgic feel of leather balls.

Disadvantages:

- Water absorption: Leather retains water, increasing weight and altering performance.

- Inconsistency: Over time, leather balls can lose shape and elasticity.

- High cost: Leather balls are more expensive than synthetic options.

2. Polyurethane (PU)

Polyurethane (PU) has emerged as a versatile and widely used material, striking a balance between affordability, durability, and performance.

Advantages:

- Durability: Resistant to wear and tear, making it ideal for frequent use.

- Water resistance: Repels water effectively, ensuring consistent play in wet conditions.

- Good touch: Mimics the feel of leather, offering excellent control and playability.

- Affordability: More cost-effective than leather, making it accessible to a wide range of players.

Disadvantages:

- Synthetic feel: Some players may prefer the natural touch of leather.

- Performance variability: Slightly less consistent than TPU in certain conditions.

3. Polyvinyl Chloride (PVC)

Polyvinyl Chloride (PVC) is commonly used in budget-friendly soccer balls and promotional items due to its cost-effectiveness and durability.

Advantages:

- Durability: Highly resistant to scratches and abrasions.

- Cost-effective: Offers an economical option for casual or recreational play.

- Weather resistance: Handles outdoor conditions well.

Disadvantages:

- Inferior touch: Lacks the finesse and feel of PU and TPU materials.

- Heavier weight: May affect flight and control.

- Environmental concerns: PVC production has a higher ecological impact.

4. Thermoplastic Polyurethane (TPU)

Thermoplastic Polyurethane (TPU) is a high-performance material used in premium soccer balls, offering durability and excellent playability.

Advantages:

- Durability: Resistant to intense wear and tear.

- Water resistance: Maintains performance in wet weather.

- Enhanced aerodynamics: Provides consistent and accurate flight paths.

- Superior touch: Matches or even surpasses leather in terms of feel.

Disadvantages:

- Higher cost: Typically more expensive than PU or PVC.

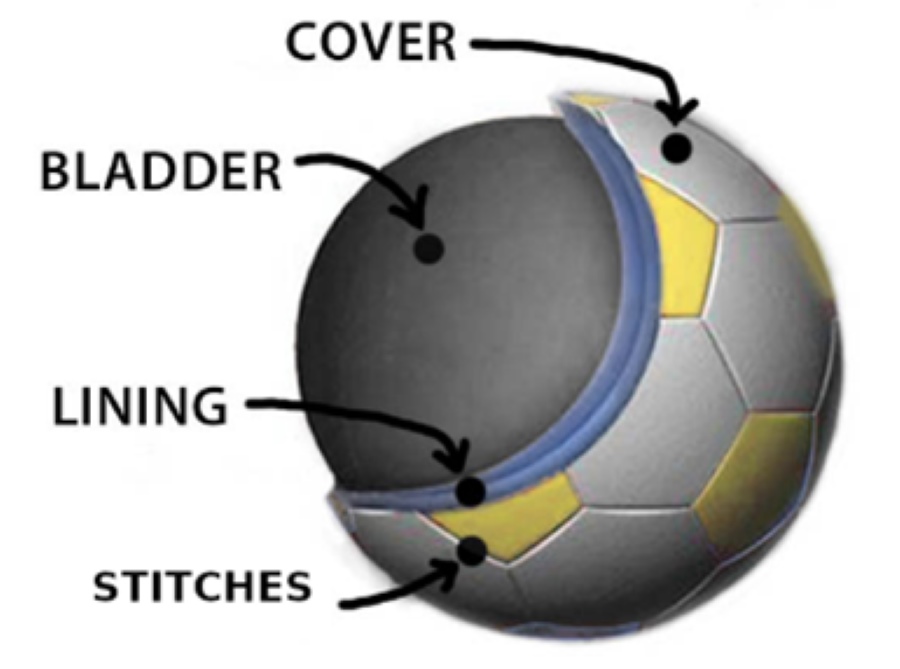

The Inner Layers: The Ball’s Core

While the outer layer determines the ball’s initial interaction with players, the inner layers shape its bounce, flight, and overall performance.

1. Bladder

The bladder retains air and determines the ball’s responsiveness.

- Butyl: Offers superior air retention, maintaining pressure for longer periods but slightly heavier.

- Latex: Provides a lighter feel and better bounce but requires frequent inflation.

2. Lining

The lining surrounds the bladder, providing structural support and influencing shape retention.

- Textile materials: Add flexibility and durability, affecting weight and rebound characteristics.

How Materials Impact Performance

The choice of materials significantly influences various aspects of gameplay:

- Flight: The outer material and panel design affect aerodynamics, influencing accuracy and flight path.

- Touch: Materials like TPU and PU provide better control and feel, enhancing precision.

- Durability: TPU and PU excel in resisting wear and tear, ensuring long-lasting performance.

- Water Resistance: Synthetics like PU and TPU repel water, maintaining consistent play in wet conditions.

- Bounce: Inner materials like latex and butyl determine the ball’s rebound characteristics, affecting gameplay dynamics.

PU, TPU, and PVC: A Material Comparison

| Material | Key Features | Use Cases |

|---|---|---|

| PU | Soft touch, durability, affordability | Professional and match-grade balls |

| TPU | Lightweight, flexible, premium performance | High-end match balls and training balls |

| PVC | Cost-effective, durable | Budget-friendly and promotional balls |

These materials are also used across various sports balls, including futsal, rugby, and volleyballs, due to their versatility.

Transforming the Game with Advanced Materials

The evolution of soccer ball materials has revolutionized the sport, providing players with options that cater to their specific needs. Materials like PVC, PU, and TPU offer distinct benefits, from the cost-effectiveness of PVC to the durability of PU and the premium performance of TPU. Each material plays a pivotal role in shaping the ball’s touch, flight, and overall playability, ensuring that players can enjoy an optimal experience on the field.

Innovations in Manufacturing

Understanding these materials allows players and enthusiasts to make informed choices, enhancing every pass, shot, and dribble with precision and confidence. Manufacturers like ASI Soccer Company, headquartered in Sialkot, Pakistan, continue to lead the industry by blending traditional craftsmanship with cutting-edge technologies. Their commitment to innovation ensures the production of soccer balls that meet the highest standards of quality and performance, catering to players at all levels.

- Facebook

- Twitter

- Linkedin

- Whatsapp